|

|

|

||||||||||||

|

|

|||||||||||||

|

It all started in May 2003 when I had the crazy idea of building my own rally car. I'd had a number of fast road cars and was heavily into karting but it was about time for a new and more involved project. After much research and advice from my friends in the motor club, I decided that a Peugeot 205 would be the ideal starting point. There were loads of bits available to get one up to scratch and parts were cheap to come by should the inevitable accidents happen! After going to see a number of cars in the local area, I came across an advert on www.rallyusedparts.co.uk for rolling shell complete with a spare donar car and most of the bits needed to get a log book. Sods law it was located miles away in the Malverns but after an initial visit and two trips later, we had a starting point....an 87' 1.6 Gti in cherry red. A shakedown date was set at a local sprint in September which gave me some motivation to get on with the work over the summer holidays. Over the following 3 months, the car was completly stripped, lightened, the cage was installed along with seats, guards, isolators, extinguishers - everything that a rally car needs to compete. I changed all of the suspension, brakes, fuel lines, brake lines, loads of new wiring - it was a complete start to finish build. The dreaded MOT followed and she actually passed first time with just the headlights and washer jets requiring re-alignment! The sprint was my first outing in a 205 and it was interesting to experience lift-off oversteer for the first time - luckily without any major mishap! I'd fitted the set of suspension which came with the car - later finding out that this was in fact forest spec and hence had an interesting sofa like ride on the smooth tarmac. The gear shift was also giving trouble as I couldn't find 3rd gear but this was eventually sorted with a new set of linkage rods. Now that I had a working car, it was necessary to find a victim to sit in the navigators seat, get a rally car log book and also pass what was then, the newly introduced "msa rally drivers course". Gren was a friend in the motor club who had won numerous sprint championships in a 205 and always expressed an interest in taking on the role of co-driver so we decided to give it a go and see how we got on. Our first event was the Longmoor Loco in late December 03 where we suffered an ignition failure on stage 2 after the newly installed rev limiter decided to cut the ignition on the start line, luckily we managed to get her restated but had already gone OTL, the event organisers let us carry on (albeit not featuring on the results sheet) but it was a great chance to see what the car could do on a tretcherous icy venue in the middle of winter. We had a fantastic day and were by now well and truely hooked!

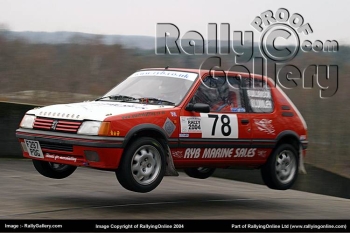

The following year we entered a number of events, the first being The Mini Tempest which is run at a military test facility called Longcross. A helpful friend in our motor club advised that the "tank ramp" which is a 1:4 hill could be taken flat out as a 205 was never going to have enough power to take off at the top...so SS1 we duefully kept the throttle down, flat in 3rd gear (then about 85mph) and the resulting photo is evidence that 205s can fly! I made the mistake of backing off in mid air which brought the nose down and meant we landed on the towing eye, what you can't see in the photo is that 60yards after the jump there is a solid concrete wall and numerous trees which have claimed many a rally car over the years. As we did more events and got used to the cars handling, it became more obvious that the std 1.6 engine was not giving us enough power to be competitive. We always worked our way up the leader board from our seeded position but with only around 110bhp, too much was being given away to the top guys in the class with nearer 180bhp. Looking around at the various options, the 1.6 engine didn't seem to have the future tuning capability that we needed so a decision was made to move into the 2 litre class. In April 2004, I purchased the first of many Mi16 engines and we set about making it fit into the car. This is an alloy block 160bhp standard engine from a Citroen Bx 16v, there is plenty of tuning capability with scope for 250bhp if you have deep pockets! We decided to install the engine with a pair of new Weber 45DCOE carbs and a modified exhaust manifold. (hopefully upping power to around 175bhp)Exhaust clearance was the main issue but we modified the downpipe where necessary and cut a section out of the tunnel to fit everything in. 5 weeks later and 20 minutes before scruiteneering closed, we made it to Abingdon with a running Mi16. The following day when the rally started it became obvious that the engine was just what we needed, plenty of mid/top range power which suited the venue perfectly. It was an extremely hot day with nearly half the 100 car entry falling by the wayside. Despite the twin fans and oil cooler, the engine ran dangerously hot and at times the oil pressure gauge was reading zero. Mid way through the last stage the engine developed a terrible knocking noise and as we crossed the finish line, it spectacularly died in a cloud of white smoke! Further investigation showed 2 cylinders showed no pressure and when the head was removed, it was clear why...... various inlet and exhaust valves were firmly embedded in the cylinder head and piston crowns having been snapped off just below the head. Amasing that we made the end of the rally! Despite the damage it was clear the Mi16 powerplant was the way forward. Their main achillies heel is oil surge and over the rest of 2004 and 2005, we experienced this with a number of different engines. Rods went through blocks, bearings were spun and events were retired from. It was clear for the following year that if we were going to continue down this route then a solution was needed. The other issue that we struggled with was the brake setup. I set of uprated disks and pads was no longer giving the necessary performance and we set about trying to find a solution. Needing to keep the std 15" Speedline wheels meant that our choice of aftermarket kits was fairly limited. I also wanted to use an "off the shelf" brake disk to keep the costs down but in hindsight this was not best for long term development. The chosen setup was a pair of 306 GTI-6 disks, hawk composite pads, Wilwood Dynalite calipers and a set of custom adapting plates which I had machined up locally. It was a tight fit which necessitated the filing down of the calipers but the end result was that they would go under the Speedlines. Initially this setup gave us some problems and resulted in a major "off" at Abingdon in mid summer 2005 after the brake pedal went to the floor just before a 90 right flat in 2nd gear - we were lucky to only damage the car and the metal spiked fence that we went though could well have come through the windscreen with dire consequences...the resulting gouges across the windscreen show how close it was! Having played around with various single master cylinders, both larger and smaller, the solution was eventually found in an adjustable AP bias pedal box with twin master cylinders. The fluid was also upgraded to a racing AP version and this gave much better tolerance to the high temperatures. With the braking sorted, attention was turned to a new engine. I did much research into the oil surge issue and after many hours of phone calls and web searches, we decided on a spec for the new engine. A new Mi16 was built with as many new parts as could be sourced - pistons, liners, bearings, oil pump, valves etc. Adjustable cam pulleys were fitted to the std cams, carbs were retained but the exhaust manifold was changed to a Longmans 4 branch, a baffled sump was installed and lastly an Accusump to combat the oil surge. The finished engine was duefully installed along with a larger capacity oil cooler and new radiator. This setup was used throughout 2006 with some great results - best was 8 o/a at Millbrook. We changed the big end bearings after every event just as a matter of course and touch wood, no more engine problems. The Mi16 engine showed that a well sorted 205 could still mix it with the top class cars but it was ultimately still lacking in straight line speed. Some of our Escort/Vauxhall rivals were running 250-300hp engines and were untouchable on the wider / faster venues. If we were going to take the 205 from a mid class car to a potential top class car, it was going to need some serious further development and investment. We had 2 options - compete as usual in 2007 or take a year off and invest in the car...we chose the latter. After much deliberation over the winter, an opportunity came up to purchase one of the original Peugeot Sport / VLR Tourning Car engines from the 2001 class winning works cars. It was a complete unit but we chose to have it completly stripped and rebuilt by Richard Longman who was the original works supplier. It was also set up on throttle boddies rather than the original plenum chamber which they ran in the touring cars. The resulting dyno runs showed it produced the expected power figures...time would tell whether it could produce the results when installed in the car! There were a number of other developments to the car including uprating the rear torsion / anti roll bars, new wider wheels, redesigned cooling and fuel systems for the engine, brake ducts to assist the front brakes, different brake pads / disks and a heavily modified front end to get everything to fit! Abingdon 07 was chosen as a shakedown event. This is a 100 car event with around 37 cars in our class. Entries include WRC Subarus, Evos, 6R4s, 306 Maxis and many powerful rwd Mk2 Escorts - we are normally pleased to get into the top 30 having usually been seeded around 60. This year we were seeded 57 and set our targets on top 15. It was going to be a tall order considdering I hadn't driven the car since we made all the changes. Anyway, to cut a long story short, despite a large spin on stage II, we finished 14th o/a and 6/37 in class...not bad when you look at what else finished ahead of us! This was the only event we planned to do this year due to the financial investment that has been put into the car. January 2008 and it's our last event in the current car - The Brean Stages. This is a fantastic rally spread across a full weekend, scruiteneering on Friday evening followed by two full days of stages. On-site accomodation and a great party on the Saturday night! Seeded 57 (again) out of 100 starters - some of the top class C competitors in the country on the entry list...it was going to be a close run for class honours! Scruiteneering was passed without too many worries and having set up service ready for the morning, we headed for the bar - for perhaps one too many pints! Saturday morning was soon upon us, it wasn't raining but temps were low and the tarmac looked (and felt) very damp. We opted for a soft compound on the front and supersoft on the back. Stages are only around 4-6 miles long so there is little time to get heat into the tyres during each run. 6 stages in all during the Saturday - all generally without a hitch. We were touching 140mph on the main straight - far too much for a rally car! The tall gearing was totally unsuited to such a tight venue and the 90 degree corners were really hampering our efforts to keep the engine revs up - much clutch slipping was required (which isn't easy when left foot braking!) With just 30 second starts intervals, we caught (and passed) many cars - often getting stuck behind slower vehicles - losing loads of time in the process. One in-car video of the same repeated 5 mile stage - on just one one particular back straight, shows us drop over 11 seconds due to getting stuck behind another car. A quick spanner check was all that was necessary on the Saturday before putting the car to bed and heading for the bar....many pints later, with the service boys (and Gren) in various states of comatose, eveyone fell into bed - very pleased with our overnight position of 21st (out of 100) and 5th in class (out of 28). Sunday morning came and everyone piled into the breakfast hall for plenty of greasy bacon, coupled with a few nurofen - the perfect hangover cure! All cars were re-seeded for the Sunday morning restart so we were now running 21st on the road - hopefully with fewer cars to hold us up. 8 stages to run, mostly without issue. The rear wheel bearings were getting progressivly more wobbly and we had to take a decision whether to risk changing them in a 20min service. The answer was no so it was at times interesting to have passive "rear wheel" steering when completly unexpected! 2 stages from the end, the exhaust manifold cried enough and promptly split across one of the welds. Completly unaccessible in the car so should we risk continue running - possibly setting fire to the car, or call it a day. I have to say my feeling was the latter but by my bossy service team were having none of it and we set off into the last stage with a tractor like sounding car hugely down on power. Much to my relief, despite the car now handling like santas sleigh and sounding like a v8 drag racing tractor, we made it to the end of SS14. The manifold had by now completly split wide open and my feet were feeling nice and toasty through the firewall! All eyes watched the timecards come in and finally the results were published.....we were 17th o/a and 2nd in class....RESULT! Got a great piece of silverware for the trophy cabinet...what a way to end all those years of development.

Since September 2007, work has started on the new shell that most of the above car will be swapped into over the coming months. Most of the spec has been decided - although I keep having crazy ideas as to how we could make it even better. I've had the wrc/btcc cage installed and we're currently in the process of prepping the interior ready for paint. I've bought loads of new bits (plus had plenty fabricated) with the idea being that both cars will be put side by side in the workshop ready to swap the bits over a fairly short period. Keep an eye on the NEW BUILD page here for further info or go the www.205gtidrivers.com forum pages for my build diary. Due to a house purchase and workshop move, things have been slow during the Summer of 2008 but things are now progressing well and we hope to be back out in the new car mid Spring 2009.

|

|

|

|

|

| Site Map |

The project begins...

The project begins... Ready for her log book

Ready for her log book Fixing the rev limiter

Fixing the rev limiter Passing another 205

Passing another 205 Pic courtesy of Mark Simms @ Rally Gallery

Pic courtesy of Mark Simms @ Rally Gallery Abingdon Rally 2004

Abingdon Rally 2004 New brake setup

New brake setup